ALLOY STEEL

If you’re being technical, steel that falls into any of these four group classifications is an alloy, but that’s not what I’m talking about right here. “Alloy steel” is different from “steel alloys.” So, what is alloy steel? Alloy steel is steel that includes about 5% alloying elements in its composition. These alloying elements can include manganese, chromium, vanadium, nickel, and tungsten. The addition of alloying elements increases overall machinability and corrosion resistance.

Alloy steel is most commonly used to manufacture pipes, especially pipes for energy-related applications. It’s also used in the manufacturing of heating elements in appliances like toasters, silverware, pots and pans, and corrosion-resistant containers.

I hope you have a better understanding of steel in general and the four groups steel is often broken into: stainless steel, carbon steel, tool steel, and alloy steel. If you’d like to learn more about stainless steel

ALLOY STEELS

|

|||||||

BS : 970

EN: Specn

|

TYPE OF APPLICTION

|

CHEMICAL COMPOSITION %

|

|||||

C

|

Mn

|

Ni

|

Cr

|

Mo

|

Others

|

||

EN -16

|

Manganese - Molybdenum Steel suitable for tensile ranges of 45/75 tons according to the ruling section.

|

0.30/040

|

1.30/1.80

|

-

|

-

|

0.20/0.35

|

S & P 0.05 Max

|

EN -18

|

1per cent chromium steel Suitable for tensile ranges of 45/65 tons accourding to the ruling section of the part

|

0.35/0.45

|

0.60/0.95

|

-

|

0.85/1.15

|

-

|

S & P 0.05 Max

|

EN -19

|

1per cent chromium - Molybdenum steel Suitable for tensile ranges of 45/80 tons accourding to the ruling section of the part

|

0.35/ 0.45

|

0.50/0.80

|

-

|

0.90/1.50

|

0.20/0.40

|

S & P 0.50 Max

|

EN - 24

|

1 1/2 per cent Nickel-chromium steel Molybdenum steel Suitable for tensile ranges of 50/100 tons accourding to the ruling section of the part

|

0.35/0.45

|

0.45/0.70

|

1.30/1.80

|

0.90/1.40

|

0.20/0.35

|

S i0.10/0.35

|

EN -30B

|

4 1/2 per cent Nickel-chromium steel Molybdenum steel Suitable for gears.agro engine connecting rounds high duty bolts,spendies exc..

|

0.26/0.34

|

0.40/0.60

|

3.90/4.30

|

1.10/1.40

|

0.20/0.40

|

S & P 0.05

Si 0.10/0.35

|

EN -36

|

3 per cent Nickel-chromium steel case hardining steel

|

0.12/0.18

|

0.30/0.60

|

3.00/3.75

|

0.60/1.10

|

-

|

Si 0.10/0.35

|

EN - 36C

|

4 per cent Nickel-chromium Molybdenum case hardining steel

|

0.12/0.18

|

0.30/0.60

|

3.00/3.75

|

0.60/1.10

|

0.10/0.25

|

Si 0.10/0.35

|

EN - 41B

|

1 1/2 per cent chromium-Aluminium Molybdenum Nitriding steel

|

035/0.45

|

0.65 Max

|

0.40 Max

|

1.40/1.80

|

0.10/0.25

|

Si 0.1/0.45

Al 0.9/1.30

S & P 0.05 Max

|

EN - 100

|

Low Alloy Steel

|

0.35/0.45

|

1.20/1.50

|

0.50/1.00

|

0.30/0.60

|

0.15/0.25

|

Si 0.50

S & P 0.05

|

EN - 353

|

1 1/4 per cent Nickel-chromium case hardining steel

|

0.20 Max

|

0.50/1.00

|

1.00/1.50

|

0.75/1.25

|

0.08/0.15

|

Si 0.1/0.35

S & P 0.05

|

EN - 354

|

1 1/2 per cent Nickel-chromium Molybdenum case hardining steel

|

0.20 Max

|

0.50/1.00

|

1.50/2.00

|

0.75/1.25

|

0.10/0.20

|

Si 0.1/0.35

S & P 0.05

|

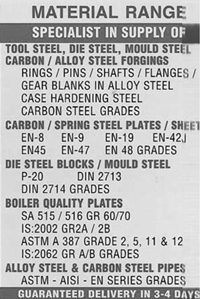

HIGH LIGHTS

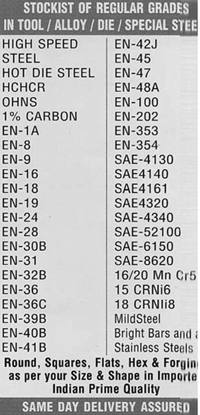

Specialists in manufacturing havey forgings / rolls / blanks / Shafts as per specific design.

Easy access to vast stock of ALLOY-TOOL-CARBON-SPECIAL DIE STEELS in complete rang of standers sizes in Round,Squard, Flat,Block,Plate,Sheet,Hexagon sections.Constant upgration of facilite to provide timely service & promt supply to clients.

Rigid Quality control at all levels we ensur top-class cent -per-cent Priem grade .

Special facility for immediat booking & supply of small orders

Bank And GST Details

Bank : Indian Bank

Branch : S.D. Road

A/C No : 454369902

IFSC Cod : IDIB000S013

GST No : 36AABCS1151N1ZB

TRADERS & EXPORTERS PRIVATE LIMITED

House of Genuine Alloy Steel