TOOL STEEL

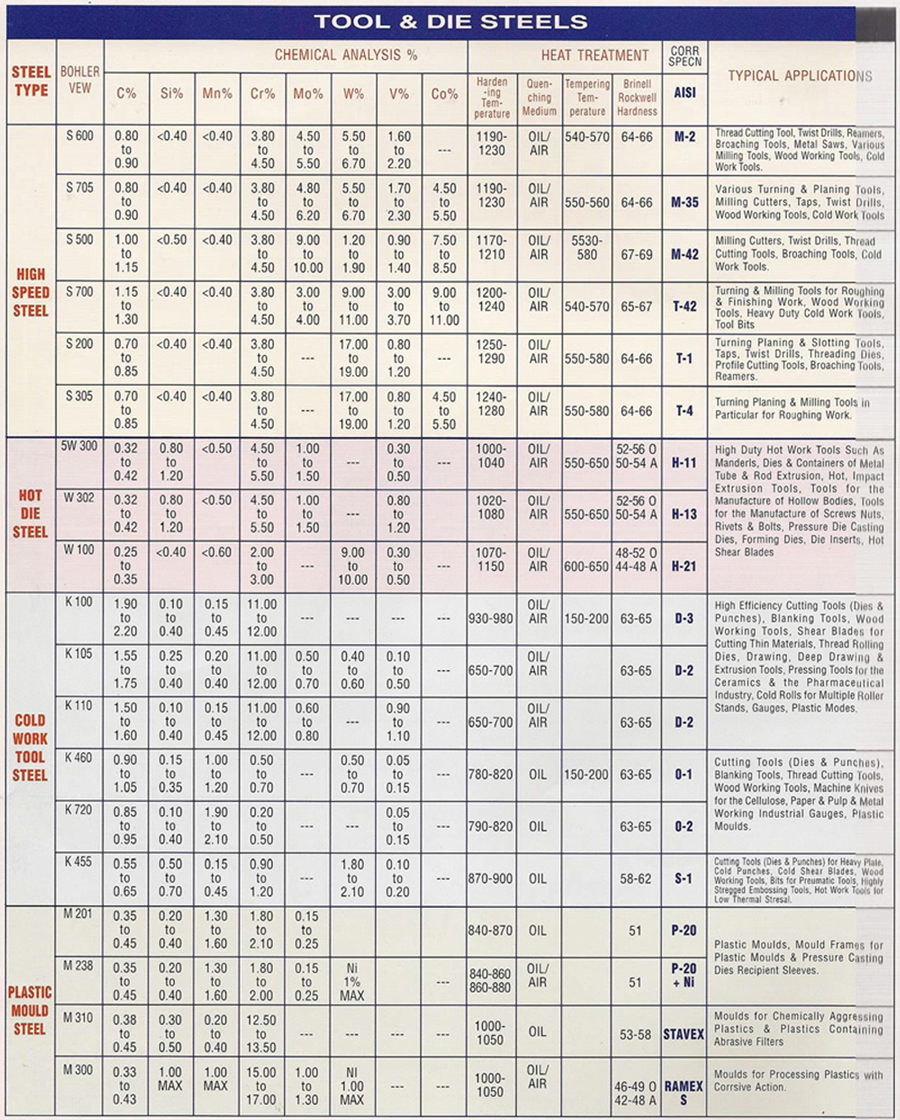

Tool steels have a carbon content between 0.5% and 1.5%. Tool steel contains other additives, including tungsten, chromium, vanadium, and molybdenum. Tool steels are known for their hardness and their ability to hold a cutting edge at elevated temperatures. This, combined with being resistant to wear and deformation, makes tool steel perfectly suited for use in machining and tool making.

DIE STEEL

Die steel is made with plain steel or alloy steel. It is used for the manufacturing of tools, which can be used for multiple purposes, including cutting, stamping, shearing, punching, chipping, etc. There are many different types of die steels that are present in the market. Depending on the way, the die steel is manufactured, the types of die steels include: - Hot work Steel : H-11, H13, DB6, P20, ( 2343, 2344, 2714, 2378) - Cold work steels : D2 , D3, O1 ( 2379 , 2080 ) - Shock resistant and low carbon tool steel - High speed die steel M2 , M35, T1 - Plastic mold tool steel P20 , P20 +Ni ( 2311, 2738 ) To increase the level of hardness of tool steels, various elements with alloying properties like chromium, vanadium, molybdenum, manganese and tungsten are added to the plain or alloy steel. These added elements make the plain steel harder and gives it stable carbides.

Bank And GST Details

Bank : Indian Bank

Branch : S.D. Road

A/C No : 454369902

IFSC Cod : IDIB000S013

GST No : 36AABCS1151N1ZB

TRADERS & EXPORTERS PRIVATE LIMITED

House of Genuine Alloy Steel